How Pringles Are Really Made

Ever tried to accommodate a bag of chips in your backpack, only to be disappointed at the powdery mess that it becomes? It's in these situations that Pringles shines. Every Pringles crisp holds its integrity no matter which dark corner you stuff the container into. The credit goes to the sturdy packaging and the engineering marvel that is the shape of a Pringles crisp. Also, who else finds that extra-loud super-clear crunch of Pringles irresistible? Many do, as it turns out, according to an Oxford University study. Basically, whatever the flavor, Pringles are irresistible. Period.

Pringles was the brainchild of Procter & Gamble. Back in the 1950s, the company was into producing edible oils. And since they had to test the quality of the oil by frying slices of spuds anyway, they wondered, "Why not just invent our own chips?" And thus was born Pringles, a snack that looked much too sophisticated than the other relatively greasy, weak, and irregular chips (tasty nevertheless) options that were around.

For years, the company remained hush-hush about its manufacturing process, too careful not to let any competitors know how they do what they do. "We'd rather have them spend the time trying to find out," the chairman then, Edward G Harness had told The New York Times back in 1975. After all, the company had spent a decade and $70 million to launch this product.

Anyway, the provenance of Pringles is no longer a secret. Here's how the crisps are crafted.

Unlike traditional chips, Pringles are not made from raw potatoes

Pringles are made from dried potato flakes, not raw slices. This cannot be waived off as a potayto-potahto situation. There is a big difference in the manufacturing process, look, taste, and feel of the chips depending on this whether the chips are made from raw or dehydrated potatoes. Traditional potato chips are made by slicing raw potatoes into pieces that are between .035 and .070 inches thick, but Pringles uses dried potatoes, which are ground into small granules. This mix is then sifted to filter out any larger flakes before adding a bunch of other ingredients. Pringles is anything but the standard potato chip.

As explained by Thrillist, the granulated potato powder gets combined with oil, water, and a "top secret mixture" that results in a potatoey paste. The secret mixture, according to the ingredient list mentioned on the Pringles can, contains "corn flour, cornstarch, rice flour, maltodextrin, mono- and diglycerides, salt and wheat starch." The dough is just thick enough to be easily poured through a funnel onto a conveyor belt. On the belt, it's spread into a thin sheet and then passed through a machine that cuts out oval-shaped slices — or "dough-vals" as they are reported to be referred to as by the Pringles factory workers.

Pringles contain less than 50% potatoes

It's 42% to be exact. The amount of potatoes used and the form in which they're used impacts the way these chips are marketed in a pretty significant way. For example, Pringles slyly tried to skirt any sort of junk food label in the U.K. The brand proclaimed that, unlike other popular potato chip brands that are simply fried potato slices, Pringles uses more of other ingredients such as wheat, rice, and corn flour, and less potato. As The Guardian reports, the U.K. court took a hard look at the ingredient list and shot down any special treatment, deeming it just as eligible for taxation as any other chip.

It wasn't the first time the debate came up either. When it was introduced in the late '60s, it was unlike any other chips on the market as it was made with dehydrated potatoes. A 1975 issue of The New York Times mentions a certain head-crunching debate about whether Pringles was even fit to be called a potato chip, as according to Webster's dictionary, a potato chip had to be made with raw potatoes, but Pringles wasn't.

The Food and Drug Administration weighed in on this and demanded that despite the snack being made with dehydrated potatoes it should still be identified as a potato chip made with dried spuds on the label — if they still wanted to be marketed as potato chips. But Pringles said no thanks and opted to be called potato "crisps."

The chips are molded to look like a saddle

After the Pringles dough is flattened and cut into small "dough-vals," a machine molds each of these thin soft-cut pieces into the shape of a saddle. Every Pringles crisp is of the same shape and size, thanks to technology. This uniformity allows the crisps to get neatly stacked one above the other like a box of folded clothes by Marie Kondo. This perfection in every chip's dimension was what the team at Procter & Gamble envisioned when they had set out to make Pringles. They wanted the kind of potato chips that once opened, didn't go stale and greasy, and when traveled with, didn't crumble in the bottom of the pack.

It was a chemist named Fredric Baur who came up with the ingenious idea of making the crisps saddle-shaped. In the mathematical world, this shape is popularly called "hyperbolic paraboloid." Architects love it for its sturdiness and ability to withstand loads. As it turns out, some architectural marvels such as the London Velodrome and the Scandinavium in Sweden are constructed in this shape as well. Besides the sturdiness, the saddle shape, apparently, is also the reason why Pringles has that extra crunchiness.

The chips are fried for about 15 seconds

There are a lot of factors to be accounted for in a traditional potato chip manufacturing unit — from peeling the potatoes to washing them, slicing them, washing them again, drying the slices, and so on. A little extra water and starch mean brittle and less tasty chips when frying. None of that applies, however, for Pringles. The dough slices are simply placed inside the saddle-shaped mold and passed through a sheet of oil until they are slightly brown in color.

The total frying time lasts for just 15 seconds — this is way less than what it would take to fry up some traditional homemade potato chips. Better Made potato chips are fried for almost three minutes, and even Frito Lay's chips are fried for over three minutes. This shouldn't be surprising as the moisture content in the dough (made with dried potato granules) that's made into Pringles crisps is quite less to start with. On the other hand, in the case of traditional chips, the moisture content has to be brought down from 80% (a potato is 80 to 85% water and 15 to 20% carbs) to 2% by frying.

The Pringles cooking machine was developed by a science fiction author

If you are a fan of the tetralogy "The Book of the New Sun", let us shine some new information on you — the author, Gene Wolfe, is why you have Pringles as your reading-time snack. Wolfe had studied robotics before pivoting into the world of writing. He said in an interview, "I developed the machine that cooks [Pringles crisps]."

Elaborating further, Wolf explained that it was a German scientist who invented the machine. "[The scientist] had invented the basic idea, how to make the potato dough, pressing it between two forms, more or less as in a wrap-around, immersing them in hot cooking oil, and so forth and so on. And we were then called in, I was in the engineering development division, and asked to develop mass production equipment to make these chips," he said.

Unfortunately, Wolfe's hard work was not enough to make the product a success soon after its launch. Pringles was a big flop. "They tasted more like cardboard than potatoes", wrote Alecia Swasy in her book "Soap Opera: The Inside Story of Procter & Gamble". P&G admitted that it took almost 25 years for it to pick up in the market, as mentioned in the book.

Only one side of a Pringles crisp is seasoned

After the chips are fried in molds, they are blown dry to make sure any excess oil is removed. The chips then travel through a conveyor belt while the seasoning is sprinkled on them. Unlike the traditional chips that are tossed in a barrel with seasoning to form a uniform coating on all sides, the creators of Pringles decided that it's enough if you season one side of the chips and leave the other bare. "Many people think that Pringles are seasoned on both sides. In fact, only the top side gets a sprinkling of seasoning in the factory," a Pringles spokesperson told The Sun. "When Pringles are stacked in their can, some of the seasoning rubs off onto the next chip – which is why they've always been a little uneven."

And because of this strange manufacturing method, there is, as it turns out, a certain way in which the chips have to be eaten. "We ask that you put it on your tongue, like a saddle. ... The primary reason for that is because we want you to eat the chip with the salted side up," Melissa Kyle, a flavor expert told Food Network. "We ask the folks to pay particular attention to the crunchiness of the chip and completely chew the chip up. Bring some air into your mouth to get the combined flavor of the chip."

It takes 20 minutes to make one Pringles tube

Once seasoned, the Pringles chips pass through a slow-moving conveyor belt, and they're ready to be stacked. It's now time for what Pringles is probably best known for — its packaging. After the chips are measured out and placed in the tubes, each tube gets fixed with its metallic bottom and is ready to be tested for quality and shipped thereafter. The whole process takes about 20 minutes. Pringles chips are made in five factories across the world with the main one in Tennessee, and there are additional factories in Belgium, Poland, China, and Malaysia.

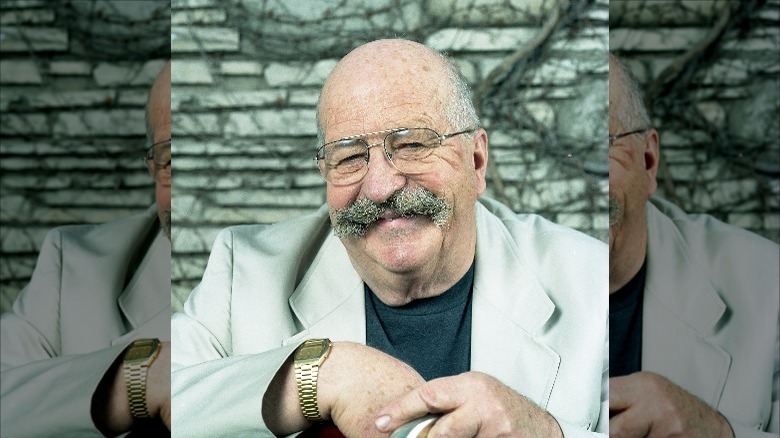

In 2016, Pringles fans in Australia took to social media to complain about a rather shrunken version of Pringles can that seemed to occupy the aisles of supermarkets. As it turned out, the brand had expanded its manufacturing process to a factory in Malaysia, which was only equipped to make cans and chips of a smaller size. These were shipped to Australia and New Zealand, irking customers about the shrunken Julius Pringles mascot (the iconic mustachioed face) and other issues such as their hands not being able to fit inside the can and an apparent difference in taste. Pringles took to its website to clarify about the change and confirm that their team would be working on improving the flavors of the chips.

The same guy who created the Pringles shape invented the Pringles tube

Fredric Baur not only gave Pringles its iconic shape, but also the tennis ball tube look-alike container. Pringles got rid of the annoying crinkling sound of polymer bags with a simple paperboard tube lined with aluminum foil and a plastic lid for a top. The packaging — which, by the way, was adjudged as a top favorite among British millennials, per The Packaging Company — hasn't undergone any change since Baur created it in the '60s. Baur was so impressed with his own work that he even requested his family to bury his ashes in one of those tubes — a wish that his children fulfilled. If you're curious about the flavor, they used the Pringles Original tube.

If we were to point out something negative about the Pringles cans, it would be the fact that they are not especially environmentally friendly. With their metallic bottom caps, paperboard body, and plastic lids, they're difficult to recycle. In an attempt to embrace sustainable packaging, Kellogg's, which owns the brand, began testing out fully recyclable cans in the U.K. in late 2020. In 2024, they finally unveiled an all-cardboard tube in England, which will hopefully lessen the chip's environmental impact.

Over 7 million quality checks are done on Pringles every year

Every crisp at the Pringles factory goes through a vigorous quality check. As mentioned in an episode of "Unwrapped," there can be as many as 7 million checks a year! Samples of chips are taken and tasted by flavor experts to test for quality at different stages. While being a chip taster might seem like a dream job, it comes with a ton of responsibility.

At the very beginning of the manufacturing process, every ingredient is evaluated to ensure that it meets the standards, at the company's lab. While sample testing is done in different stages, the final test seems the most crucial. A flavor expert picks filled tubes of Pringles randomly and takes them into a specific testing room where they are compared with an already tested tube of a "perfect" batch.

The testing room is lit in red light so as to hide the color of the chips and, in turn, negate the chances of any preconceived notions about whether it's raw, overcooked, over seasoned, etc. The flavor experts take a bite out of different tubes of chips to check for "doneness, seasoning, texture, and salt," as explained in the show. Even if one chip from the lot seems off, all the chips produced in that batch are scrapped.

All Pringles flavors are made in a lab in Battle Creek, Michigan

Though Pringles was the brainchild of Procter & Gamble, it was sold to Kellogg's in 2012. With the change in ownership, the headquarters of the stacked-chip brand moved to Battle Creek, Michigan. Of course, they do have factories where the chips are manufactured, but all the flavor experiments happen in Battle Creek.

While it all started with the original salted one, today, Pringles has over a 100 flavors, including a few wacky ones such as white chocolate peppermint, seaweed, and prawn cocktail. Then, of course, there are the crowd favorites such as sour cream and onion, BBQ, and cheddar cheese. "There will sometimes be flavors we work on for year — like our babies — only to have them die an unceremonious death," flavor expert Jay Henry told Thrillist. Every flavor is created in-house by two people experimenting with different powders until something clicks. It takes years before a flavor gets approved and makes its way into production.